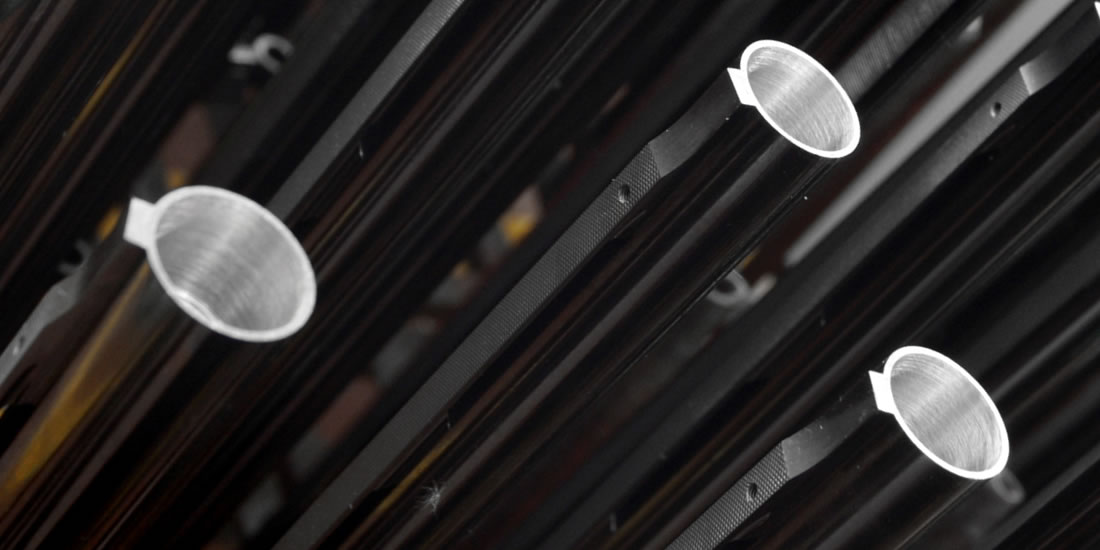

The best barrels

Maximum precision for Breda dynamic sporting and hunting shotguns

Breda sporting shotguns, semiautomatic for hunting and O&U are among the most appreciated products known by sportsmen and hunters from all over the world. The distinctive feature that unites them is the particular attention paid to the design and production of the barrels, an extremely important phase for its engineering impact on the whole shotgun, capable of determining its performance and value.

What distinguishes a good-quality shotgun barrel from a high-quality barrel?

Ballistic skills for careful design

Metallurgical skills for a careful selection of materials

Mechanical skills for precise and scrupulous machining and processes

Chemical skills for treatments that guarantee the durability of the product

Only the best steel for Breda barrels

Every single barrel used for Breda dynamic or semiautomatic shotguns is made from tri-alloy steel with certain chemical-physical features: a raw material that requires long supply terms and strict controls on arrival, that therefore requires very precise and organized planning. The Quality Control department is responsible for evaluating, identifying, certifying and tracking incoming materials and then directing them to the different stages of the production process.

Cutting, drilling and machining

The processing of the barrels continues with cutting to size operations and the deep drilling phase. This allow to obtain a very elastic and high-performance barrel, without any surface tensions. The production cycle continues with a series of internal and external mechanical processes on the chamber, on the forcing cone, on the barrel core and on the choke. The barrel is then polished by porous ceramic inlays, called “stones”, that polish the surfaces, guaranteeing very reduced roughness and surfaces finely polished to mirror effect, thus ensuring a frictionless firing.

Binding and welding of the rifle barrels

It’s then time to proceed with the ligature of the rib and the tenon, a strictly manual operation carried out by expert craftsmen who, with extreme care and attention, bind the barrel without creating tensions that may cause damages during the welding phase in oven. The welding of the barrels of Breda dynamic shotguns, semiautomatic and over&unders are performed by means of Castolin welding, an alloy composed of silver-copper-zinc-tin, whose melting point does not interfere in any way with the molecular structure of the barrel, leaving the elastic properties unaltered.

Manual finishing of the barrels

The process ends with manual finishes made by craftsmen with long experience and high levels of technical know-how: surface polishing, external finishing of the barrel and further treatments such as external blueing and internal chrome plating, are part of a process that lasts at least one month and that guarantees our customers that Breda over&unders, sporting and hunting shotguns are safe, high-performance and valuable products.

A HISTORY OF SUCCESSES…

The history of Breda shotguns has its roots in one of the most renowned industrial groups of the 20th century in Italy. Since then, Breda shooting and hunting shotguns have become a true icon in the world of sport shooting and in the art of hunting, gaining a place of honour in the hearts of those who still today preserve their own weapons with care and dedication. Breda is history, it is emotion, it is passion, it is family.

A PASSION FOR DETAILS…

Breda brings its creations to life in the armoury district of Val Trompia, Brescia, where master craftmens with long experience and superfine taste operate their craft. The precious decorations are conceived and designed by artists and master engravers who create suggestive plant compositions, modern avant-garde themes, evocative faunal scenes or even graceful metaphorical figures, capable of giving Breda shotguns a refined and elegant style, always recognisable and to great effect.

AND A SEARCH FOR PERFECTION…

First-class materials, impeccable mechanical workmanship and state-of-the-art assembly are the advantages of a high added-value production that characterises the Breda brand for the production of shooting and hunting shotguns. Once the raw materials have been selected, the expert hands of the artisans proceed with the mechanical processing and surface treatments to create a highly performing product.